This page, 'Hydro Generator Cooling', should be part of a frames system at www.tfd.chalmers.se/~lada/projects/proind.html

Hydro Generator Cooling

| Researcher: |

Pirooz Moradnia pirooz@chalmers.se |

||||||||

| Supervisor: |

Håkan Nilsson hani@chalmers.se |

||||||||

| Examiner: |

Lars Davidson lada@chalmers.se |

||||||||

| Cooperation: |

C3SE, Chalmers VG Power AB Vattenfall Research and Development |

||||||||

| Sponsors: | The Swedish Water Power Center | ||||||||

| Publications: | [-] | ||||||||

| Start of project: | July 2008 | ||||||||

BACKGROUND The hydro power companies spend a large amount of money on maintenance of their generators. The deterioration of the generator components can, to a large extent, be assigned to the temperature loads that arise when the generator is operated intermittently. The cause of the deterioration may also be due to insufficient or uneven cooling. Cooling air flow through the generator is used to minimize the deterioration of the generator due to high temperatures. The losses associated with the air cooling are however responsible for a substantial amount of the total generator losses. When the periphery speed is high the ventilation losses may amount to as much as half of the total loss. For a machine with lower peripheral speed the losses amount to approximately 5% of the total losses. Thus a more effective ventilation system would make the generator more efficient. The main objective of the project is to, from a fluid mechanical point of view, create conditions to reduce machine damage and efficiency losses that can be related to poor/ineffective cooling.

PROJECT

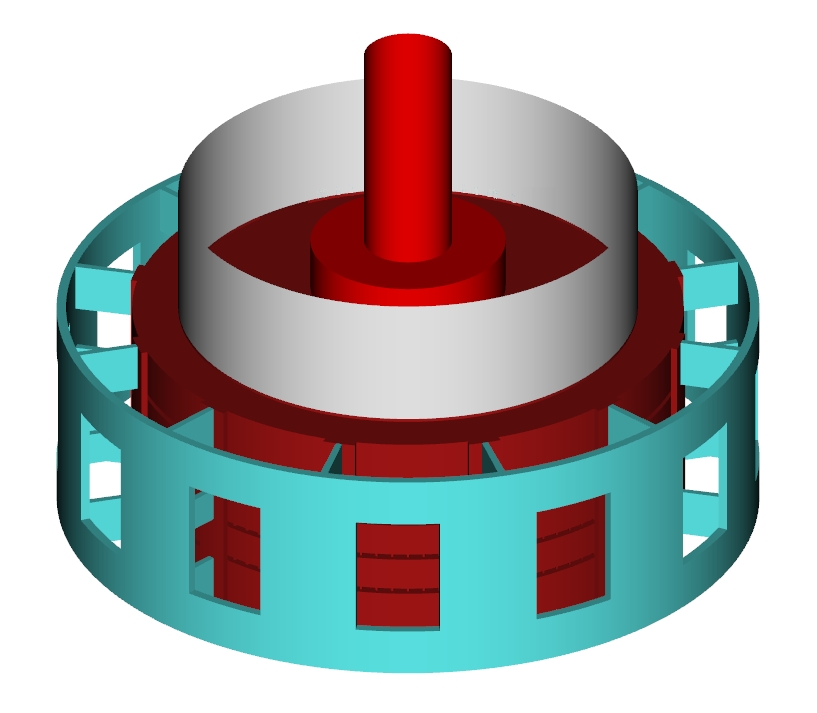

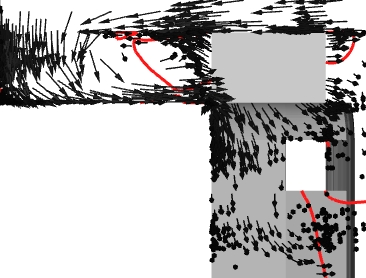

The ultimate goal of the project is to numerically simulate the heat transfer inside a generator, with a high accuracy. This requires a good knowledge of the cooling air flow within the machine, which is rather complex and unsteady. Therefore, the main focus of the project, at first hand, is to resolve the air flow in a generator. Once the air flow is numerically determined down to details, the heat transfer simulations can be started. The simulations are performed using the open-source CFD software

OpenFOAM.

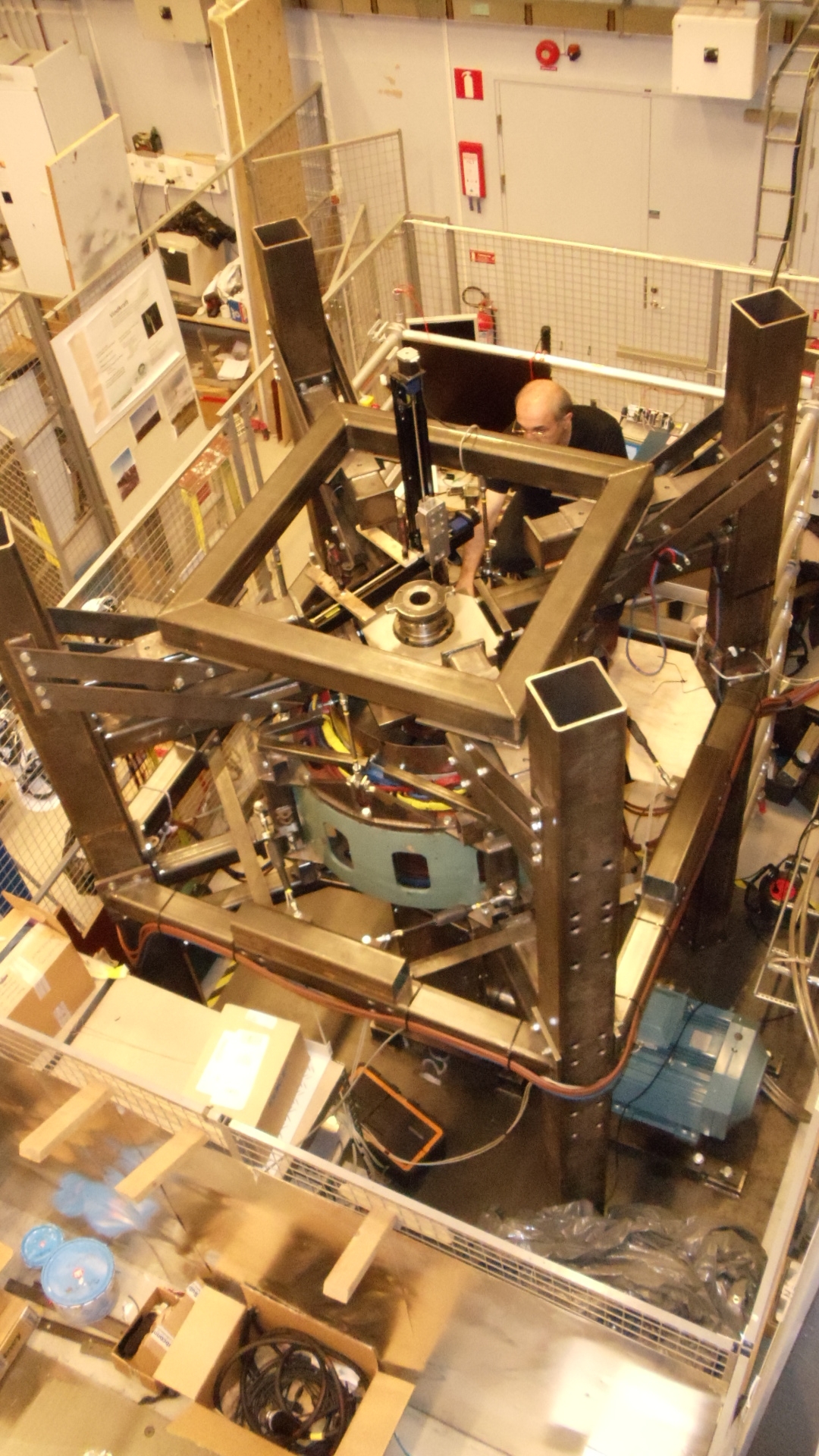

Though the project focuses mainly on numerical simulations, experimental measurements are needed to validate the numerical results. A small generator at Uppsala University is chosen to base the numerical modelings and experimental measurements on.

RESEARCH CARRIED OUT UNTIL FALL 2010

FUTURE WORK PUBLICATIONS If you download a document or have any comments concerning the work or the web-page, please send me an e-mail or let me know by filling up this form:

- click BACK TO TOP |

||||||||

|

This page, "Hydro Generator Cooling", should be part of a frames system at www.tfd.chalmers.se/~lada/projects/proind.html |