Tutorial on “Axial

Compressor” theory and specification for “Overhaul of Gas Turbine Parts”

The compEDU

sessions given as part of the gas turbine technology course are devoted to two

chapters:

- Axial compressor theory:

familiarize yourself with compEDU and ease learning of axial compressor

theory (secondary reading material).

- Overhaul of Gas Turbine parts:

learn about how gas turbines are operated, maintained and overhauled

(primary reading material).

The learning tool has been introduced in the

course because last years students felt that a stumbling block in learning

about axial compressor theory is the difficulty to visualize the processes

described in the book. The hope is that the many images and illustrative

explanations will ease this burden, making the learning more efficient.

Additionally, references to some videos

supporting the lecture notes are given below.

For more information on the compEDU effort

check out http://www.energy.kth.se/compedu/Compedu_home_asp/main/default.asp.

A personal license including a DVD for installing the program on your home

computer can be purchased for 300 SEK.

Axial compressor theory

The axial compressor theory chapters is used to

introduce you to working with compEDU. This session is intended to support the

reading of the course book. Hopefully, you will go home with a feeling that you

know what axial compressors is all about, after only about one hour of

studying.

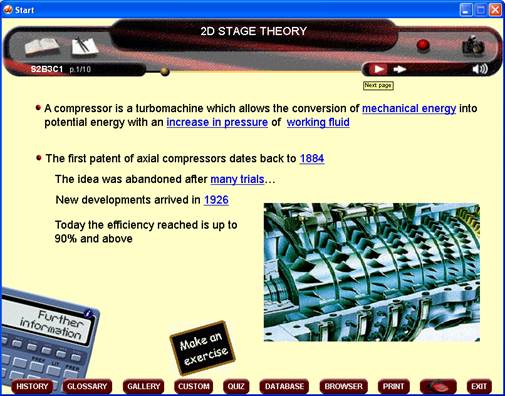

Start book

S2B3 and select Chapter 1, that is S2B3C1. Work through the 2D stage theory.

Make sure that you check all links that you find interesting. For example, what

new developments regarding axial compressors were introduced in 1926?

Use the

next page button to browse through the material.

Make sure

you master the five “fundamental concepts” mentioned in the summary.

Overhaul of Gas Turbine

Parts

Start

S2B14C1. As you go through the chapter try to find answers to the following

issues:

- Why is the expected life of a

low pressure turbine longer than for a high pressure turbine?

- What materials are used in gas

turbines and approximately where are they used. Check some limiting

temperatures for some common alloys. What is an approximate upper pressure

ratio for an axial compressor considering current limits on nickel based

alloys?

- How can the remaining life of a

gas turbine part be tested? What is the “surface replication method”? How

does this process differ between aero and stationary gas turbines?

- What is “preventive” and

“predictive” maintenance?

- What is trend analysis and

“fault indices”? What gas path measurements are usually required to

perform engine diagnostics.

- Which parameters influence the

operating and maintenance cost for a gas turbine engine?

- What is:

- Creep

- Erosion

- Corrosion

What governs these three deterioration

mechanisms? How do they arise and where in the engine?

- Give four “key-service

factors”. What is meant by them?

- Define different levels of

disassembly inspection.

- What is the typical overhaul

interval (major inspection) for a stationary gas turbine?

- What does EOH mean?

- What is a birth history list?

- What aero engine failure

conditions are considered safety critical? What do they mean?

Videos supporting lecture

notes

It is frequently

claimed that the compressors are generally more difficult to design

aerodynamically than the turbines. This is mainly attributed to the adverse

axial pressure gradients of compressors, that is the flow is in the direction

of increasing pressure, causing blade and end wall boundary layers to grow more

rapidly than in turbines. In particular, an optimal included angle of

divergence of about seven degrees is suggested for radial compressor diffusers.

Recall the slide:

An old, but

very illustrative video for this flow phenomena is given in compEDU. Select the

“BROWSER” tab below in the compEDU main screen. Choose videos and start the

S2B1C3 video (flow in a diffuser).

When discussing

gas turbine stressing the following slide was used:

High cycle

fatigue was attributed to rotor stator interaction, that is the trailing

boundary layer of the turbine nozzle impinges on the rotors at high frequency

(compared to low cycle fatigue). Start the S5B1C6 (midspan section of a

turbine) video for an illustration of this phenomena.