|

Simulation of near bell paint break-up in electrostatic painting |

| PhD student: |

Björn Andersson, Fraunhofer-Chalmers Centre/Chalmers bjorn.andersson@fcc.chalmers.se |

| Supervisor: |

Lars Davidson lada@chalmers.se |

| Co-supervisor: |

Valeri Golovichev, Chalmers valeri@chalmers.se |

| Industrial co-supervisor: |

Andreas Mark, Fraunhofer-Chalmers Centre andreas.mark@fcc.chalmers.se |

| Sponsors: | Fraunhofer-Chalmers Centre, Vinnova |

| Publications: | [1-4] |

| Start of project: | November 2009 |

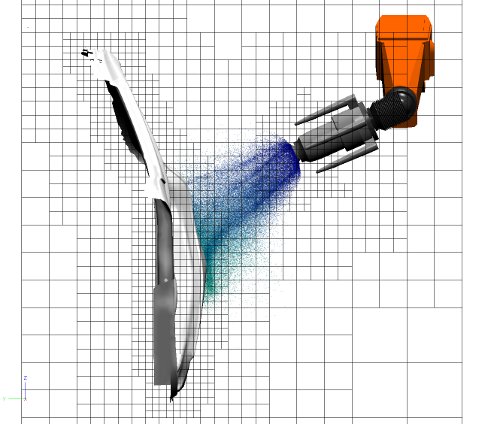

BACKGROUND Paint and surface treatment processes in the car paint shop are to a large extent automated and performed by robots. Having access to tools that incorporate the flexibility of robotic path planning with fast and efficient simulation of the processes is important to reduce the time required for introduction of new car models, reduce the environmental impact and increase the quality. In spray painting paint primer, color layers and clear coating are applied through the Electrostatic Rotary Bell Sprayer (ERBS) technique. Paint is injected at the centre of a rotating bell; the paint forms a film on the bottom side of the bell and is atomized at the edge. In the current version of the FCC software IPS Virtual Paint the atomization step is not simulated instead measurements of droplet size and velocity distributions close to the bell are required as input.

PROJECT

The objective is to predict the size and velocity

distributions of the droplets at some small distance away

from the bell where the break-up is completed. To achieve

this, the Lagrangian method Smoothed Particle

Hydrodynamics (SPH) is chosen for the liquid paint phase.

The larger volume fraction of the air part is on the

other hand handled with an Eulerian Finite Volume solver.

In the project the two discretization methods are coupled

and models of the relevant physics in the paint break-up

are developed and implemented.

REFERENCES

|

|

This page, should be part of a frames system at www.tfd.chalmers.se/~lada/projects/proind.html by Webmaster: Ingalena Ljungström ilj@flowsim.se |