|

|

|

| PhD student: |

Maryam Mirzaei marmir@chalmers.se |

| Supervisor: |

Lars Davidson lada@chalmers.se |

| Co-supervisor: |

Fredrik Innings, Tetra Pak Fredrik.Innings@tetrapak.com |

| Cooperation: |

Prof. Ahmad Sohankar, Isfahan university of technology, Iran asohankar@cc.iut.ac.ir |

| Sponsors: | Ministry of Science, Technology and Research of Iran |

| Publications: | [-] |

| Start of project: | September 2011 |

| End of project: | - |

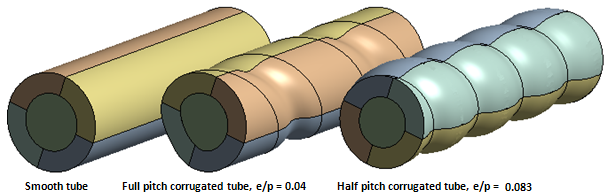

BACKGROUND Today heat Exchangers are widely used as an important component in heat transfer area. Depending on the application of heat exchangers in the industry, several methods are used for increasing the heat transfer with a reasonable pressure drop. One of these methods is using the corrugated tubes which increase the amount of heat transfer by producing recirculating flow. The recirculation regions increase the turbulence in flow, decrease the thickness of the thermal boundary layer and increase the heat transfer.

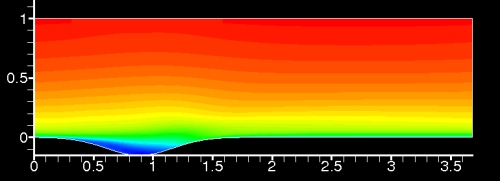

PROJECT In order to simplify the simulations, we will initially study the flow in a plane channel where the lower wall is corrugated, see the figure above. The advantage of a plane configuration (channel) to a circular one (pipe) is that the extent of the domain in the spanwise direction is smaller than the perimeter of the pipe. Hence a smaller mesh can be used. The CALC code is used for both LES and DNS simulations.

REFERENCES |

|

This page, LES of heat tranfer in corrugated channels, should be part of a frames system at www.tfd.chalmers.se/~lada/projects/proind.html by Webmaster: Ingalena Ljungström ilj@flowsim.se |